As most of you know I am a huge fan of the entry-level PCP known as the Umarex Gauntlet which comes in .177, .22 and .25 calibers. I have been pretty vocal to Umarex regarding the issues that Gauntlet has which could be addressed relatively easily and not really incur any additional machining/fabrication time to correct. The issue is that there are thousands of these parts that are already rolling off the line and an introduction into an already rolling production line will cause a huge ripple effect in delivering the product on time.

So as with most manufacturers, the product will go through generational upgrades and changes over time. Well, some of the comments that folks have made are finding their way to the generational evolution of the Gauntlet. Some of the main issues with the Gauntlet were:

- Weak Barrel Support

- Cracked Air Strippers

- Difficulty Cocking

The poor barrel stiffness issue caused huge point of impact changes with only slight physical contact with the barrel shroud was made. The POI issue was solved by the community with things like barrel bands, woodblocks and other ingenious ways to support the barrel shroud. I offered a barrel band which introduced additional support from the bottle to the barrel shroud, Well Umarex picked up on this issue and quickly designed an integrated barrel shroud support system that attached to the bottle block. This barrel shroud support that is being included on the then new .25 Caliber, was promised to previous Gauntlet owners as a part that would eventually be available. It was also said that this new improvement would be included on any fractional generation .177/.22 caliber Gauntlets produced.

The Umarex Gauntlet barrel shroud support on the .25 worked well and folks were banging Umarex's doors down to be able to add this to their .177/.22 Gauntlets. The addition of the support required some drilling and mechanical fastening which could be installed improperly and cause additional issues that the manufacturer was not ready to accept. So, after a few 30 or parts were sold the support line was lit up with calls of installer error or difficulty installing the part. Umarex quickly stopped offering the part and offered the support as a service that they would perform and send the rifle back to the shooter. As you can imagine this additional shipping back and forth made the shipping companies a lot of money and put the airgun owner in a position where they were without their beloved Gauntlet for a week or more plus the shipping cost.

Well as I stated earlier, the factory is retrofitting existing stock with the upgrades like:

- Barrel Shroud Support.

- Beefier Air Stripper.

- Better fitting O-ring on Air Stripper.

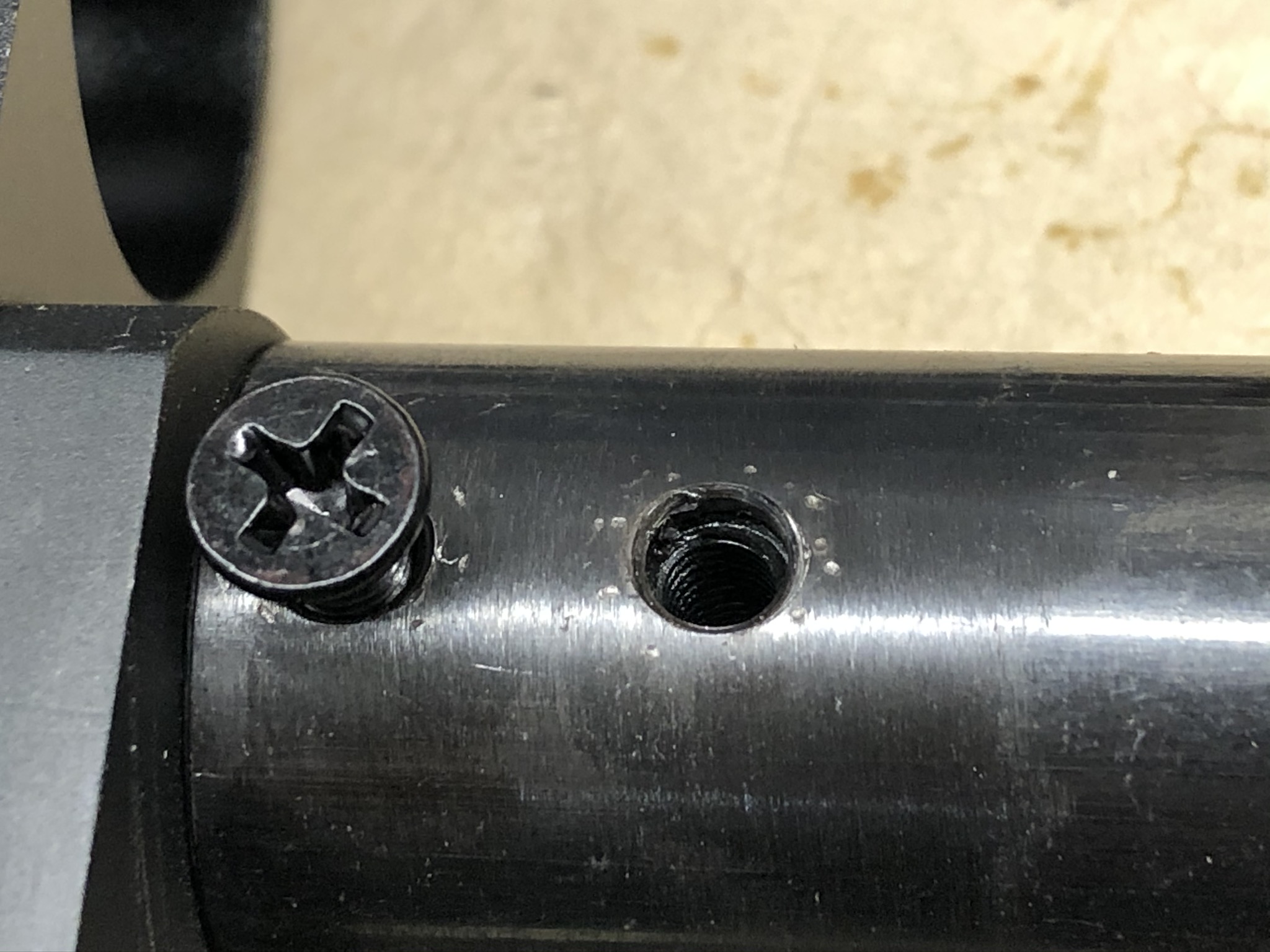

- Stronger screws at the bottle block.

I know this because, in one of my recent airgun orders of 12 rifles, all the .22 caliber versions were upgraded. Look at the photos here and you will see that they are hard at work to improve the Gauntlet for the end-user and this is awesome to see. The images I provided are of a .22 caliber and show the improvements that were made to an existing stock rifle, the reason I know this is that the star washer imprints in the pressure tube are clearly visible. I also have erased the last digits of the serial number as this will be in the hands of a customer at some point and I do not what their serial number used by some unscrupulous characters that may exist out there ?

I will continue to report changes as I discover them and will try my best to field any questions you may have.

Be Safe!

Hajimoto

IMAGES: