A few years ago I published some articles in the airgun forums and community that I have referred folks to read but recently found our that some of the forums have changed there format or layout which broke the links I had to the articles. I have decided to writ it here on Hajimoto Productions blog so it is easier to find and refer to.

There has been a growing trend where paintball regulator and tank swapping techniques have made their way over to the HPA / PCP world and this should not be happening. Please let me explain, Co2 produces around 800 psi of pressure so a removable bottle with a ball or pin seal can be removed without much of an issue. That said, if you examine the internal and the regulator threads of a used paintball gun, you will witness substantial wear to the threads.

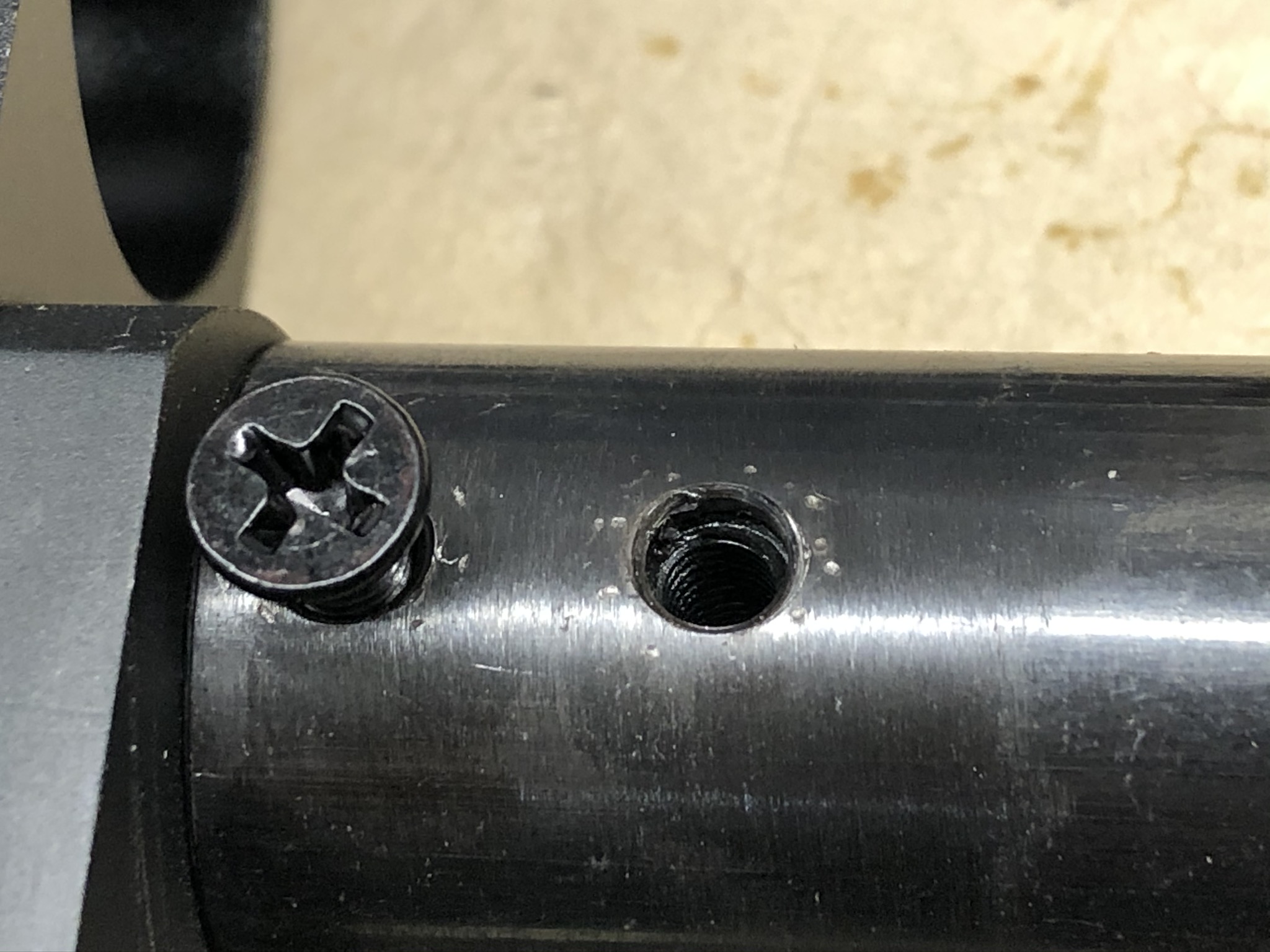

When you start hitting 1400PSI or higher there is an incredible amount of stress exerted on the regulator bonnet threads and the PCP threads. They begin to gall and wear excessively when being screwed in or out under pressure.

Anything over 1200 psi should have the ball seal or pin seal removed to prevent the bottle from being filled off the PCP and then screwed on which is why most of your higher operating pressure bottle guns (except FX which has a very well engineered close tolerance activation gap on the internal valve) cannot be filled off the PCP.

Case and point is the newly released Gauntlet 30 caliber which still uses a paintball style regulator but the output pressure or operating pressure is 2800psi. Paintball threads were never designed to deal with those pressures and be actively threaded on or off.

I know we have all seen videos or articles where the instructor shows how you loosen the bottle and shoot down the pressure remaining in the PCP you can easily remove the bottle. The initial loosening of the bottle causes the thread damage. If you do not believe me, look at the galling of the thread of some bottles that have been removed or installed under pressure, they will be thinner and razor-sharp as the metal is deformed during this process.

While the thought of carrying around another tank that can be swapped in if needed seems like a great idea, its not. Install and align your regulator and tank and leave them installed. Always refill the tank on the PCP and if you need to service anything, degas the PCP and then unscrew the regulator and tank.

Do yourself a solid, don't install or remove your bottles under pressure without understanding that you are reducing the service life of that part.